Advancing the Historic Clayton Silver Mine in Idaho

A 50-year producer with USD $660,000,000* in historic output, now an advanced exploration project with significant untapped potential

Clayton Silver Mine Operations

Highlights

- Mining Operations 1935 – 1986

- Absentee owner in 1980s used older mining methods.

- Inferior mining techniques and old processing equipment diluted grade milled

- Mining ended in mid 1980’s due to low metal prices with active mine operations still in mineralization.

- The historic production disclosed from the Clayton Silver Mine, mainly of silver, lead and zinc, has an aggregate present value of approximately USD $660 million+ based on current spot metals prices.

Clayton Silver Mine Operations

Highlights

- The historic production disclosed from the Clayton Silver Mine, mainly of silver, lead and zinc, has an aggregate present value of approximately USD $660 million+ based on current spot metals prices.

- Mining Operations 1935 – 1986

- Absentee owner in 1980s used older mining methods.

- Inferior mining techniques and old processing equipment diluted grade milled

- Mining ended in mid 1980’s due to low metal prices with active mine operations still in mineralization.

INVESTOR INFORMATION

Clayton Silver Project Overview & Locality

The Clayton Silver Mine was discovered in the late 1800’s and historically was one of the most active underground mines in the Bayhorse Mining District in central Idaho for lead, zinc, silver, and copper with minor gold. Based on current spot metal prices the Clayton Mine historical recorded ore production would have been equivalent to approximately USD $660,000,000

Located approximately 30 km south-southwest of Challis in Custer County, central Idaho, the 1,028 acre property consists of 29 patented mining claims and two patented mill sites aggregating approximately 562 acres, and 20 unpatented mining claims adjacent to and surrounding the Company’s patented claims covering an additional 466 acres.

Clayton Silver Project Claim Map

Explore the Property

Project Highlights

- The Clayton Silver Project is a high-quality asset

- Excellent assay results from successful 2023 TOMRA Ore-Sorting test program

- Patented claims include surface ownership rights.

- No government royalties, minimal property maintenance costs.

- No legacy environmental issues.

- Accessible year round; paved road to site

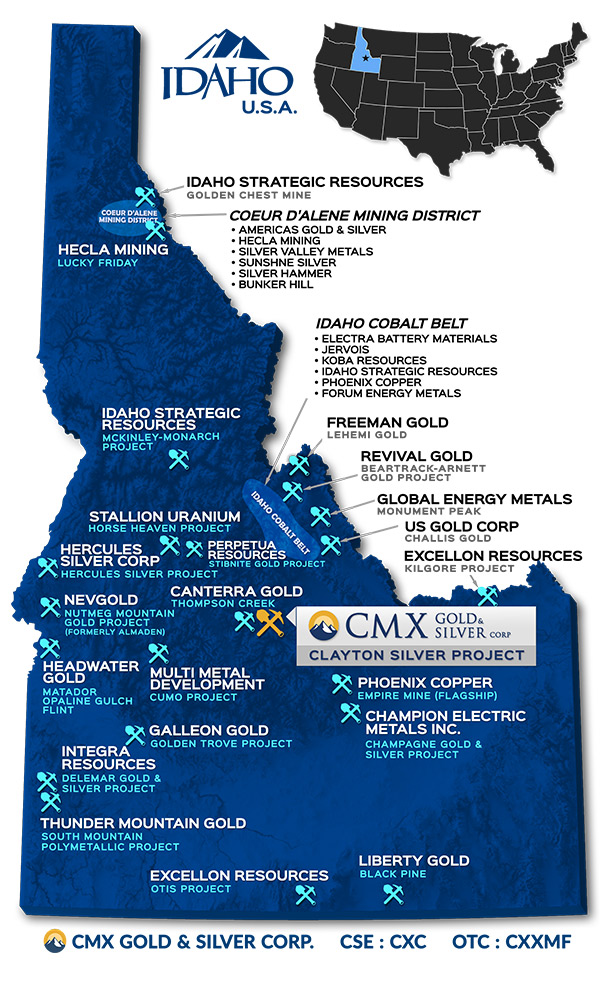

- Idaho is a mining friendly jurisdiction & ranked #7 in the world on the Investment Attractiveness Index

- No drilling permits required for patented claims

- Advanced exploration project has excellent potential for adding resources and deposits.

- Existing data highlights big upside from low risk drilling programs.

- The Clayton Silver Mine is an example of a replacement deposit in carbonate rocks

Additional Info

1,000,000 Tonne Mine Stockpile Exploitation Potential at Clayton

The Clayton Mine stockpile consists of mineralized rock that was not processed through the mill as the grade was not considered high enough at the time it was mined. The stockpile is estimated to contain in excess of 1,000,000 tonnes of mineralized material readily available for immediate processing.

In May 2022, the Company signed an agreement with Sulphide Remediation Inc, a firm specializing in mineral processing utilizing precision X-Ray ore sorting technology to produce high-grade concentrate from mine stockpiles for subsequent delivery to a toll mill.

Compared to average grades documented in the Company’s 2014 stockpile evaluation program , ore-sorting increased the silver grade by 6.4 times and the lead and zinc grades by 7 times. The success of TOMRA’s ore-sorting to enhance the grade of the metals of interest in the stockpile is confirmed by the excellent assay results. Ore-sorting is a proven technology utilized successfully around the world to recover metals from historically mined material. Testing confirmed the Company’s expectation that it would work well on the stockpile material.

1,000,000 Tonne Mine Stockpile Exploitation Potential at Clayton

Our stockpile consists of rock that was not processed through the mill as the grade was not considered high enough at the time it was mined. The stockpile is estimated to contain 1,000,000 tonnes or more of mineralized material readily available for immediate processing.

In May 2022, the Company signed an agreement with Sulphide Remediation Inc, a firm specializing in mineral processing utilizing precision X-Ray ore sorting technology to high-grade mine stockpiles of unprocessed rock to enhance the grade of material delivered to a toll mill.

Compared to average grades documented in the Company’s 2014 stockpile evaluation program , ore-sorting increased the silver grade by 6.4 times and the lead and zinc grades by 7 times. The success of TOMRA’s ore-sorting to enhance the grade of the metals of interest in the stockpile is confirmed by the excellent assay results. Ore-sorting is a proven technology utilized successfully around the world to recover metals from historically mined material. Testing confirmed the Company’s expectation that it would work well on the stockpile material.

OBTAIN™ – AI-Powered Ore Sorting

Explore the future of AI ore sorting

OBTAIN™ – A groundbreaking deep learning technology for TOMRA’s sorters, revolutionizes ore sorting by enabling precise detection and classification of individual particles, even when clustered.

OBTAIN™ is an industry-first: single-particle precision in high-throughput ore sorting. This revolutionary software uses a Neuronal Network to identify the properties of each particle accurately and independently of the sorter’s capacity, achieving unparalleled precision and reliability in detection and ejection. Based on their specific requirements, mining operations have the flexibility to either enhance the throughput of the sorter while maintaining consistent sorting efficiency or improve sorting precision without compromising the existing throughput. It is a true game changer.